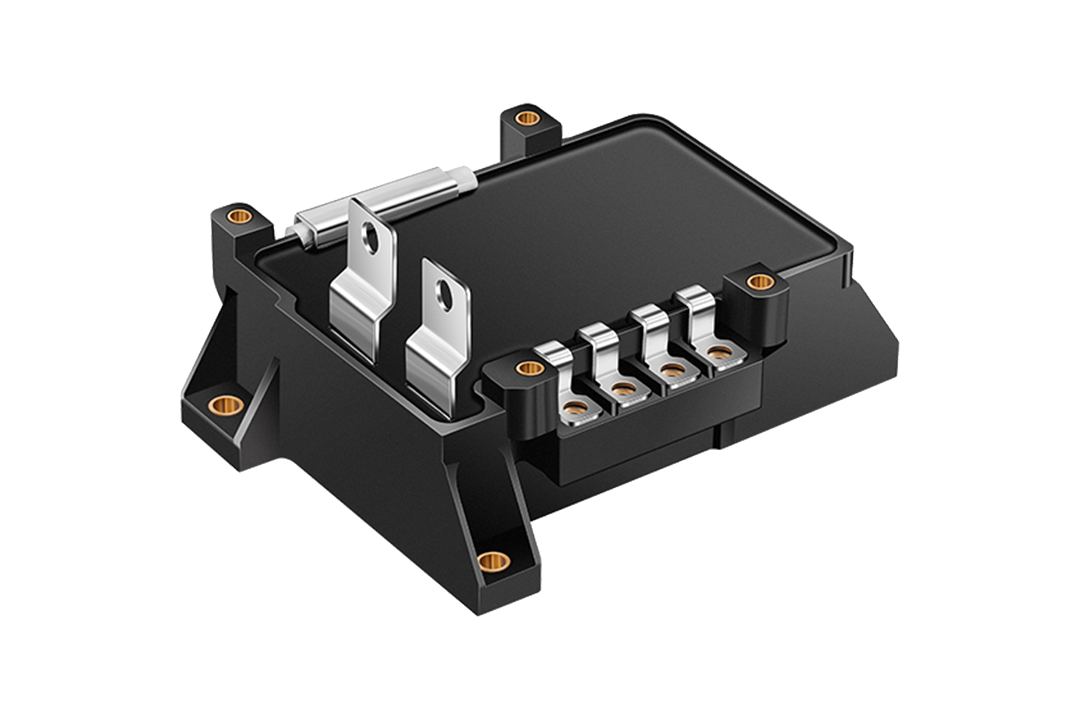

New energy vehicle capacitor customization

MKP-QB Series

|

Model |

450-1100V / 80-3000uF

|

Parameters

|

Imax=150A(10Khz) |

AEC-Q200 |

Ls ≤ 10nH (1MHz) |

IEC61071:2017 |

|||

-40~105℃ |

|

|||

|

Features |

High ripple current capability high withstanding voltage capability |

|||

|

Compact size, low ESL. | ||||

|

Safety film design with self-healing properties. | ||||

|

Applications |

DC filiter circuits. |

|||

|

Electric and hybrid passenger vehicles. | ||||

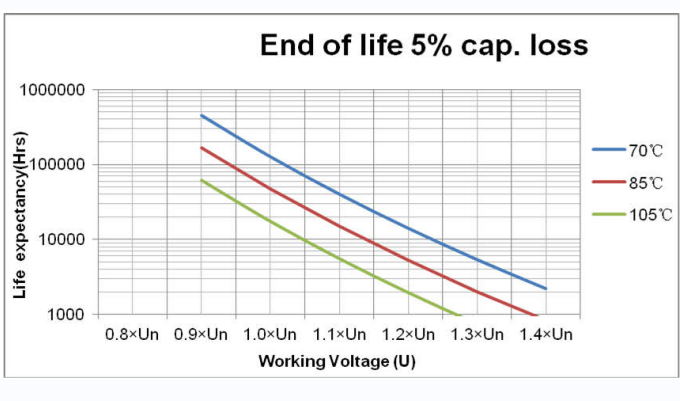

Capacitor charging and discharging

Storage environment requirements

● Humidity, dust, acid, etc. will have a deteriorating effect on capacitor electrodes and must be paid attention to.

● Especially avoid high temperature and humid places, the storage temperature should not exceed 35℃, humidity should not exceed 80%RH, and the capacitors should not be directly exposed to water or moisture to avoid water intrusion and damage.

● Can not be directly exposed to water or moisture, so as to avoid moisture intrusion and damage to the capacitor.

● Avoid drastic temperature changes, direct sunlight and corrosive gases.

● For capacitors that have been stored for more than one year, please check the electrical performance of the capacitors before using them again.

Humming sound due to film vibration

● The humming sound of a capacitor is due to the vibration of the capacitor film caused by the Coulomb force of the two opposite electrodes.

● The more serious the voltage waveform and frequency distortion through the capacitor, the greater the humming sound produced. But this hum.

● The humming sound will not cause any damage to the capacitor.

● The insulation of the capacitor may be damaged when it is subjected to overvoltage and overcurrent or abnormally high temperature or at the end of its life. Therefore, if smoke or fire occurs during the operation of the capacitor, disconnect it immediately.

● When smoke or fire occurs during operation of the capacitor, the power supply should be disconnected immediately to avoid accidents.

Tests