DC Link Automotive Film Capacitor for HEV with High Performance (MKP-QB Series)

MKP-QB Series

|

Model |

800V/1000uF

|

Parameters

|

Imax=240A(10Khz) |

AEC-Q200 |

Ls ≤ 16nH (1MHz) |

IEC61071:2017 |

|||

-40~105℃ |

|

|||

|

Features |

High ripple current capability high withstanding voltage capability |

|||

|

Compact size, low ESL. | ||||

|

Safety film design with self-healing properties. | ||||

|

Applications |

DC filiter circuits. |

|||

|

Electric and hybrid passenger vehicles. | ||||

Spike and Surge Protection

Unless otherwise specified, all tests and measurements shall be carried out in accordance with the test standards specified in IEC 60068-1:2013, 5.3.

Atmospheric conditions.

Temperature: 15°C to 35°C;

Corresponding humidity: 25% to 75%;

Barometric pressure: 86kPa to 106kPa.

Prior to measurement, the capacitor shall be stored at the measurement temperature for a sufficient period of time to allow the entire capacitor to reach this temperature.

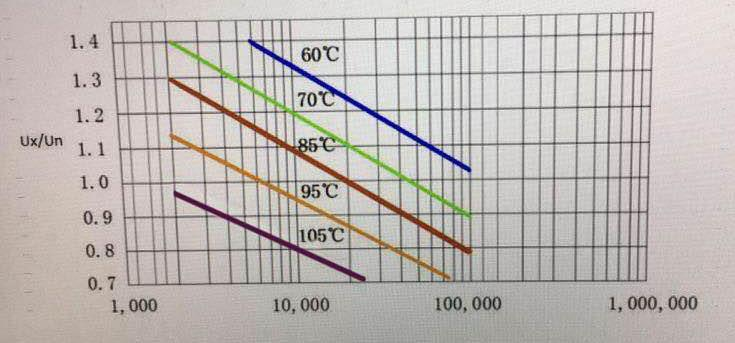

Life curve